We will mark your details■

Thanks to the cooperation of CUBE SYSTEMS and Keyence a family of laser marking solutions for industrial use was created. LaserMarker offers scalable product marking solutions that can be adapted to almost any specialized requirement. Keyence marking heads and top-class components provide our marking machines with high efficiency and resistance in difficult industrial conditions.

Make such markings as

- Logotypes

- Graphic patterns

- Barcodes

- QR codes

- Serial numbers

Perfect for marking on:

- Paper

- Plastic

- Glass

- Wood

- Ceramics

You can use LaserMarker to mark recipes on the most demanding materials, from various angles, as well as on spatial objects. Thanks to their compact structure, easy installation and the possibility of quick retrofitting, they are used in many applications and industries such as automotive, food, electronics, FMCG and many others.

Does it sound interesting?

Select your marking machine

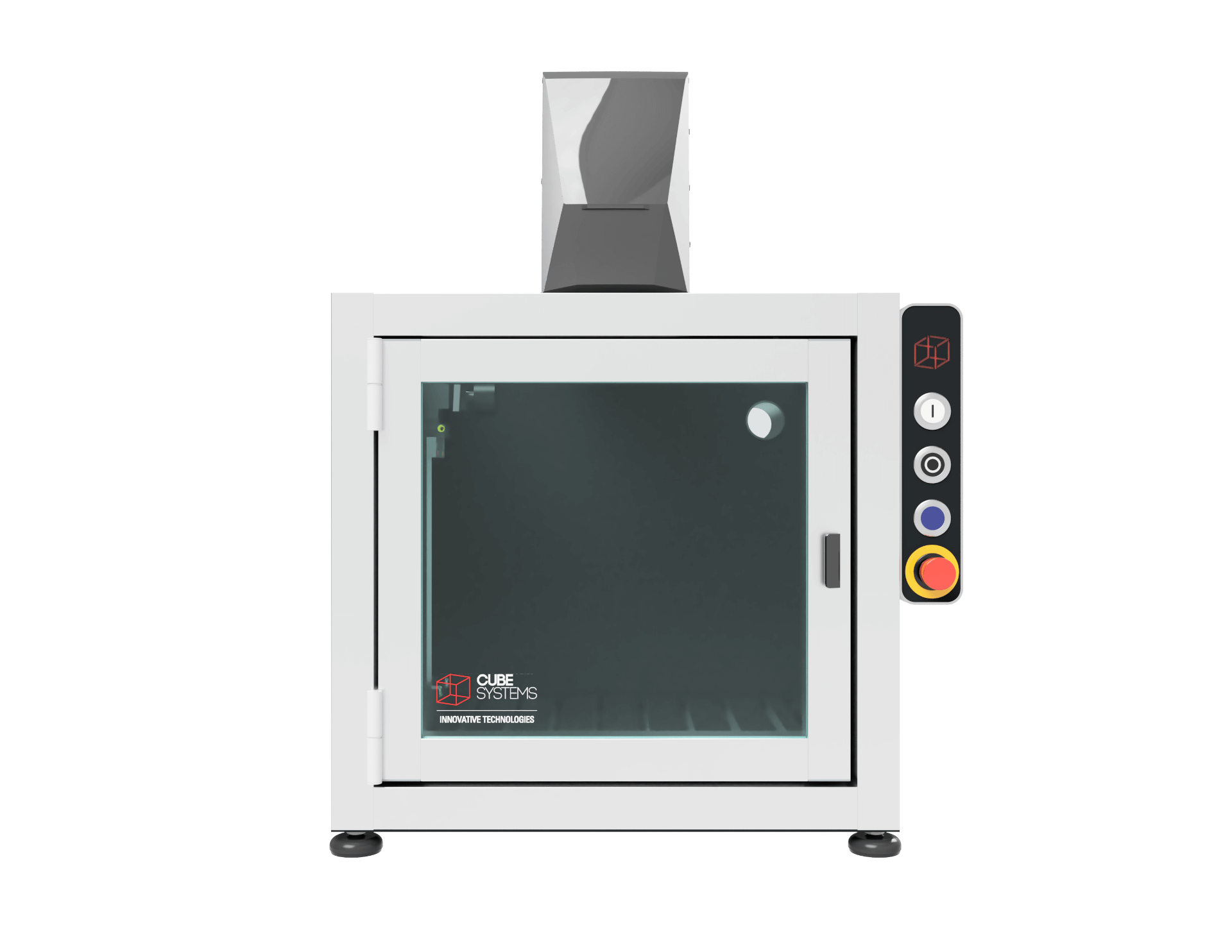

MINI |

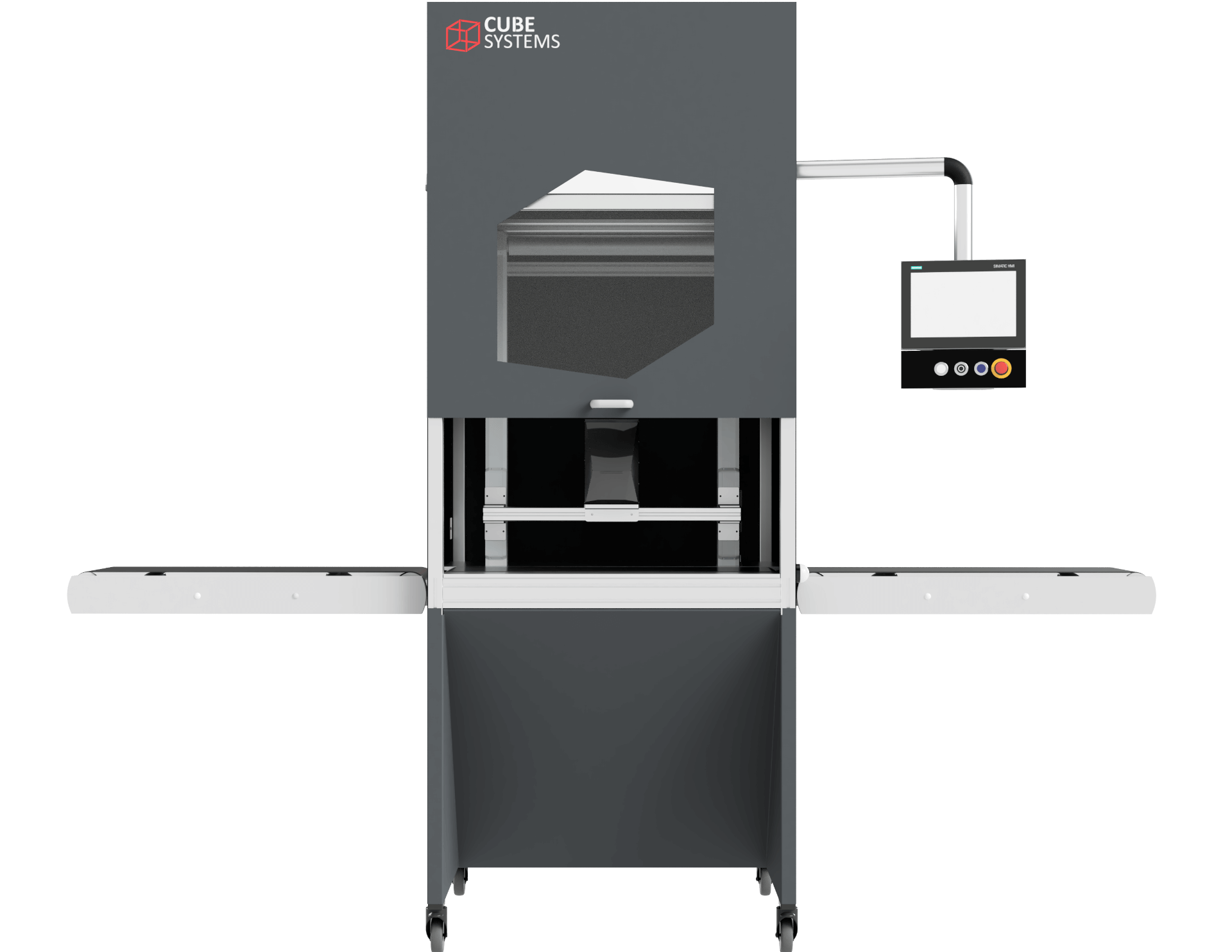

STANDARD |

ROTARY |

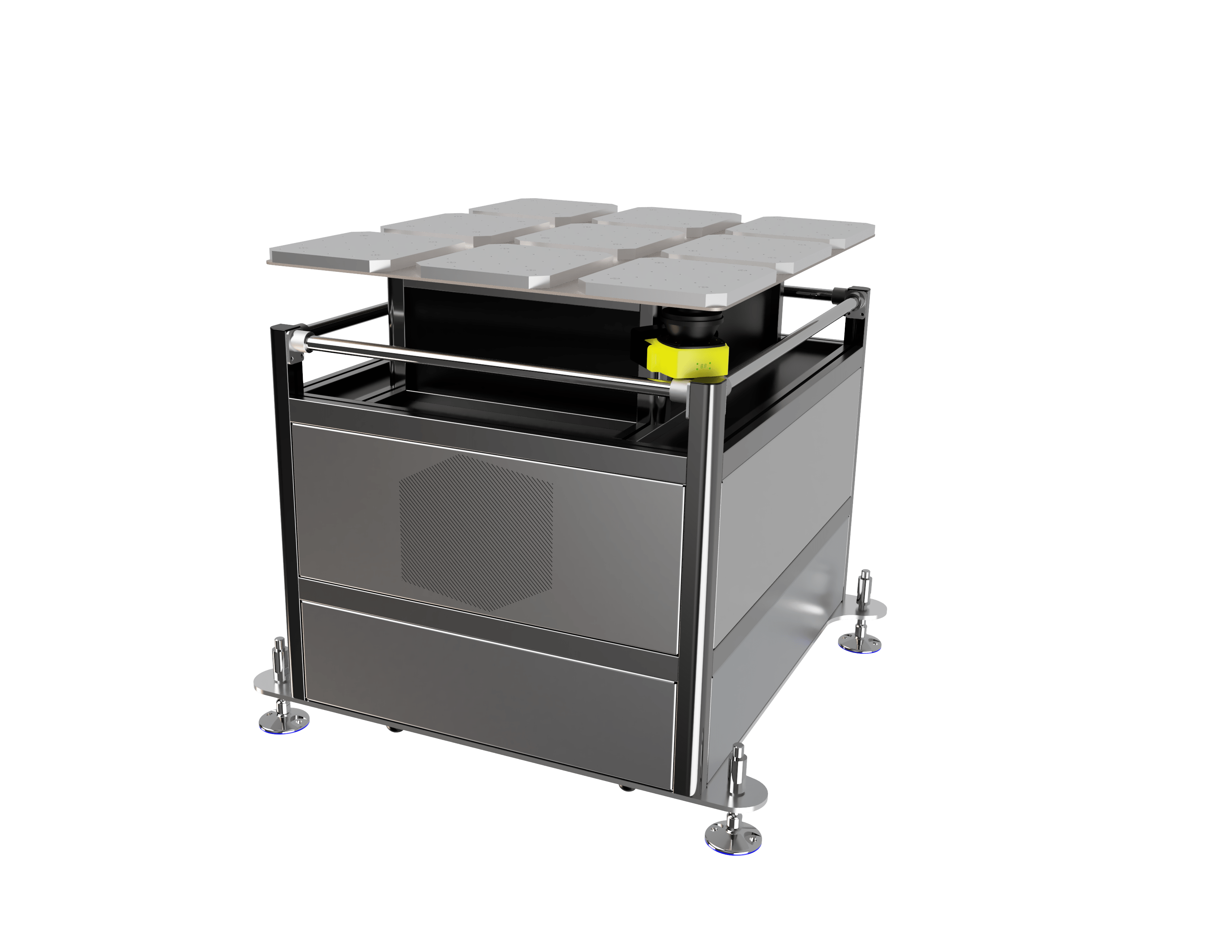

PLUS |

FLOW |

|

|---|---|---|---|---|---|

| Do you have limited work space? An ideal solution for individual orders, short series and when space is limited. The marking machine can be placed on a desk and you can start working immediately after connecting it to the socket. | Do you have standard needs for marking individual elements or fixtures with details? We have the perfect solution for most laser marking applications. Easy to install and quick to run. | Do you need to mark small series in a short time? A rotating table allows you to speed up marking tasks, tasks by replacing parts during the marking cycle of subsequent elements. | Non-standard dimensions of marked elements? The head placed on movable XYZ axes is able to automatically position itself over a detail with non-standard dimensions or a tray with many elements from a given batch. | Do you need full process automation? A marking machine with a belt conveyor will be perfect for your production hall. Items to be marked can be delivered and picked up without having to stop the process. | |

| Max. detail dimensions [mm] (WxLxH) |

400x400x250 | 950x350x550 | 450x300x300 | 1250x800x350 | 950x350x550 |

| Marking area [mm] (LxB) |

125x125 or 330x330 depending on the marking head used | ||||

| Adjustment X [mm] | 0 | +/- 220 | 0 | +/- 450 | +/- 220 |

| Adjustment Y [mm] | 0 | 0 | 0 | +/-250 | 0 |

| Adjustment Z [mm] | +/- 125 | +/-220 | +/- 225 | +/- 175 | +/-220 |

| Marking machine dimensions [mm] (WxLxH) |

580x580x740 | 970x860x2100 | 970x1300x2200 | 1500x1360x2000 | 970x860x2100 + conveyors 2x1000mm |

As well as...

Each marking machine has the following features:

- Automatic visual inspection of marking quality

- Assembly table with grooves for mounting detail fasteners

- Easy maintenance

- Access to the work area secured by a lockable switch

- Built-in interior lighting

- Connection enabling connection of dust extraction from the marking zone

- Protective glass with a filter enabling viewing of the laser operation

- Intuitive signalling of work status

- Intuitive HMI panel for preparing and selecting marking programs[1]

- Precise, manual height adjustment of the work table[2]

Optionally, you can also order:

- Non-potential alarm outputs

- Possibility of integration with other machines

- Automatic height adjustment of the work table

- Possibility of integration with ERP systems

- Fume extraction system

[1]Optional equipment for the MINI version

[2]For the PLUS version, automatic height adjustment is a standard version

Which head will be suitable for your process?

| Material | Name of the material | UV head MD-U |

Hybrid head MD-X |

Fiber head MD-F |

C02 head ML-Z |

|---|---|---|---|---|---|

| Resin | EP (epoxy resin) | ■ | ■ | ■ | ■ |

| ABS (polymer resin) | ■ | ■ | ■ | □ | |

| PBT | ■ | ■ | ■ | □ | |

| PA | ■ | ■ | ■ | ■ | |

| PC (polycarbonate) | ■ | ■ | ■ | ■ | |

| PP (polypropylene) | ■ | ■ | ■ | ■ | |

| PE (polyethylene) | ■ | ■ | ■ | ■ | |

| PET | ■ | x | x | ■ | |

| PPS | ■ | ■ | □ | ■ | |

| PS (polystyrene) | ■ | ■ | □ | ■ | |

| PI (polyamide) | ■ | □ | □ | □ | |

| PVC (polyvinyl chloride) | ■ | ■ | ■ | ■ | |

| Resin glass | ■ | ■ | ■ | ■ | |

| Metal | SUS (stainless steel) | ■ | ■ | ■ | x |

| Fe (iron) | ■ | ■ | ■ | x | |

| Al (aluminium) | ■ | ■ | ■ | x | |

| Ni (nickel) | ■ | ■ | ■ | x | |

| Cu (copper) | ■ | ■ | ■ | x | |

| Au (gold) | ■ | ■ | □ | x | |

| Other | Ceramics | ■ | ■ | ■ | ■ |

| Si (silicone) | ■ | ■ | □ | □ | |

| Paper | ■ | ■ | ■ | ■ | |

| Rubber | ■ | ■ | ■ | ■ | |

| Glass | ■ | x | x | ■ | |

| Wood | □ | □ | □ | ■ |

■ = suitable □ = possible x = not suitable

The table above indicates general use. The optimal model selection depends on the detailed conditions of use.

| Application | UV head MD-U |

Hybrid head MD-X |

Fiber head MD-F |

C02 head ML-Z |

|---|---|---|---|---|

| Durable | ■ | ■ | ■ | ■ |

| Marking on metal | ■ | ■ | ■ | x |

| Marking on transparent details | ■ | x | x | ■ |

| Marking on resin | ■ | ■ | ■ | □ |

| Large marking area | ■ | ■ | ■ | ■ |

| Marking small details | ■ | ■ | ■ | □ |

| Marking on the move | ■ | ■ | ■ | ■ |

| High accuracy | ■ | ■ | ■ | ■ |

| Simple maintenance | ■ | ■ | ■ | ■ |

| Cutting, drilling, peeling | ■ | ■ | ■ | ■ |

| Trimming | □ | □ | □ | x |

| Minimizing the installation area | ■ | ■ | ■ | ■ |

| Difficult environmental conditions | ■ | ■ | ■ | ■ |

| Cost optimization | ■ | ■ | ■ | ■ |

| Logo-typing | ■ | ■ | ■ | ■ |

| Operating from a computer | ■ | ■ | ■ | ■ |

■ = suitable □ = possible x = not suitable

The table above indicates general use. The optimal model selection depends on the detailed conditions of use.

Extend functionality

Universal Mobile Work Platform

The Universal Mobile Work Platform for the MINI marking machine is a solution intended for applications where frequent change of the installation location is required. While maintaining all the features of the workstation, the UMPR platform allows for easy rearrangement of the workspace, depending on current production needs. The use of transport wheels and the light and compact structure mean that moving the platform does not require the use of internal transport. The scalability of the solution allows you to adapt UMPR to specific technological requirements.

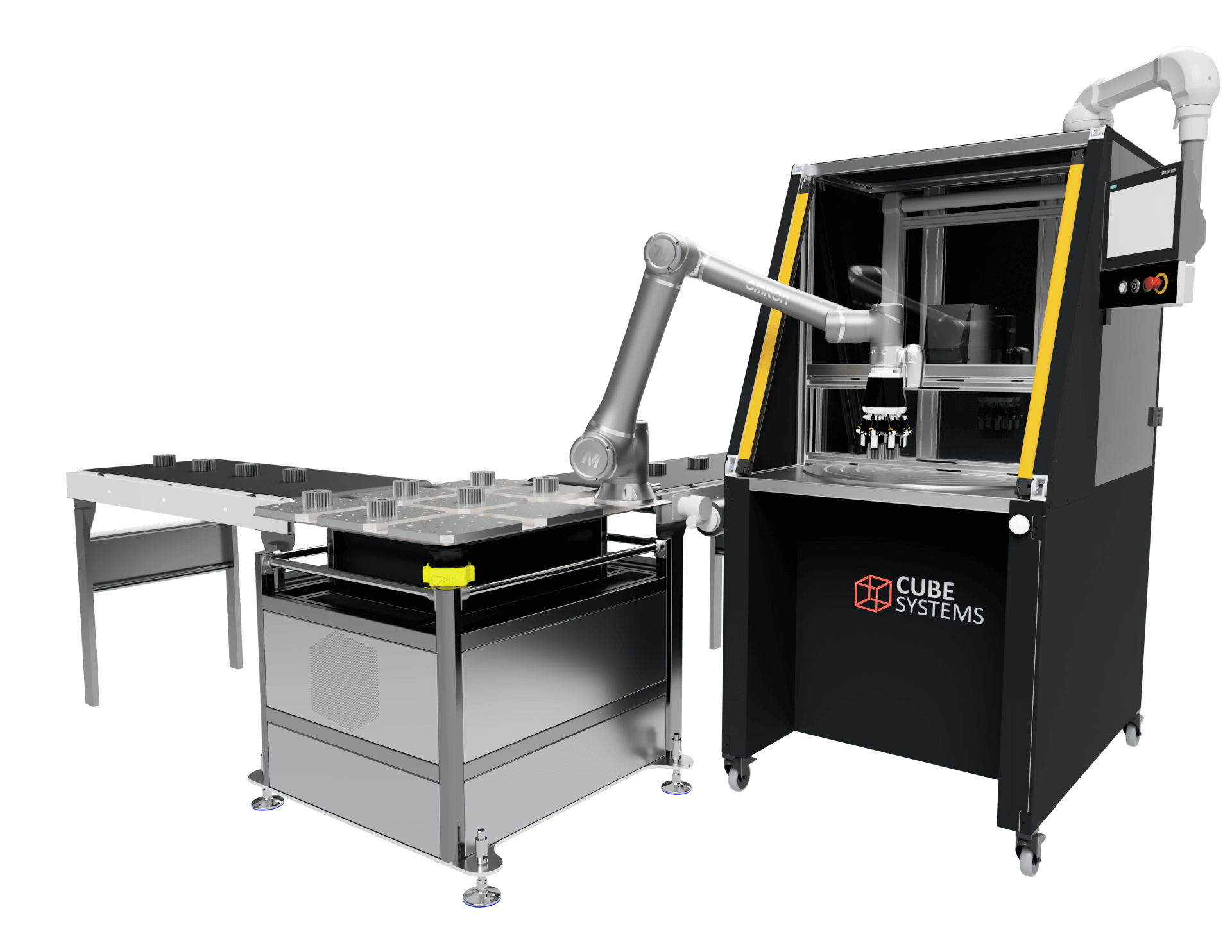

Integration with cobots

Increased work efficiency at the LaserMarker marking station using a collaborative robot. The use of cobot features enables full automation of the marking process. Without the need for formal integration, a robot collaborating in the marking machine's work cycle delivers and receives details. During this time, the operator can engage in other activities that add value to the entire production process. The solution guarantees an appropriate level of security. The use of a corobot allows easy retooling and easy change of installation location.

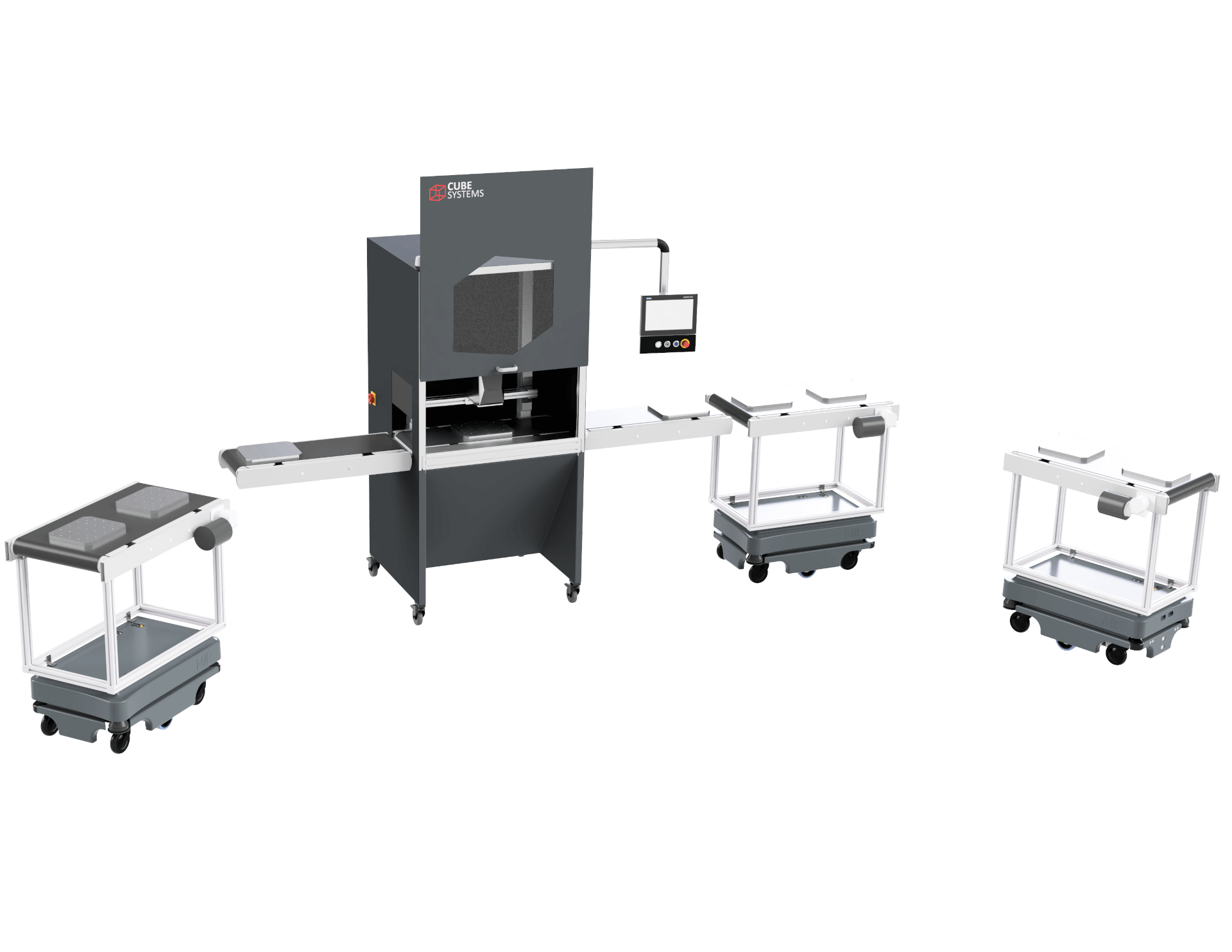

Cooperation with AMR (autonomous mobile robots)

Autonomous transport of parts to marking machines. The perfect solution at the end of your production processes. Thanks to the installation of belt conveyors adapted to the height of the marking machine on AMR robots, the entire process can be carried out without the participation of an operator. Details from the process are delivered to the marking machine and, on the other hand, received and transported to the next process or to the warehouse. The solution guarantees full work safety. Together with the robots, AMR robot fleet and path management software is provided.

English

English  Polski

Polski Deutsch

Deutsch